|

|

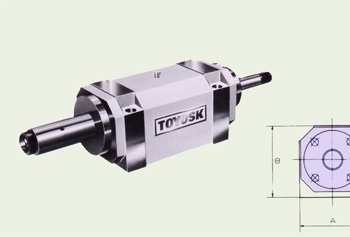

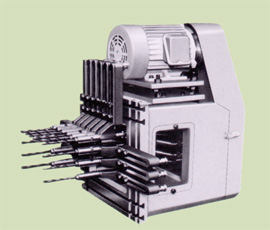

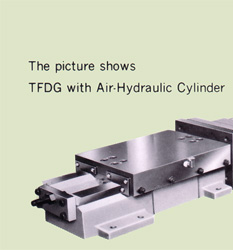

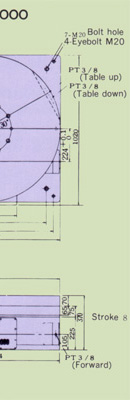

FEED UNITS |

TOYOSK FEED UNIT has the high ability based on our long-term experiences and

productions. It is available for not only all of TOYOSK Multi-Spindle Units but also another unit.

It is designed for easy maintenance and equipped with telescopic metal

cover as standard. |

| secf FEED UNIT SERIES |

|

|

|

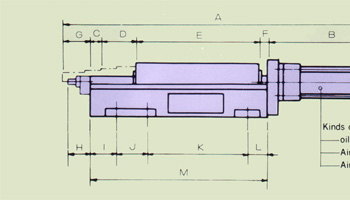

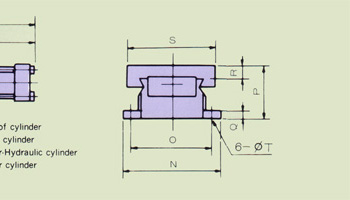

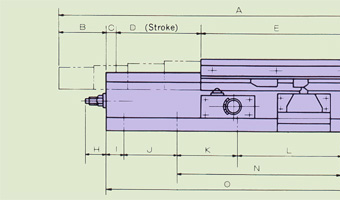

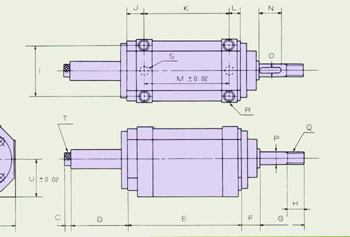

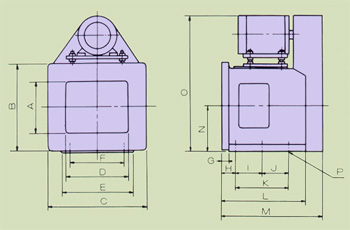

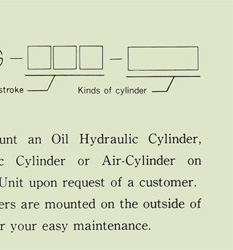

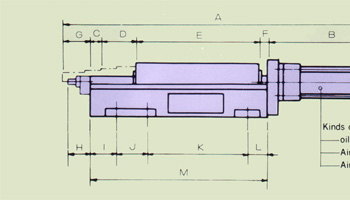

Feeding

Cylinder |

Weight |

A |

B |

C |

Stroke

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

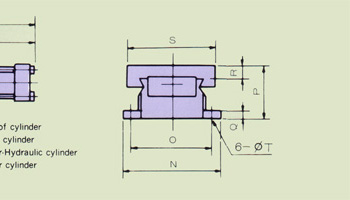

N |

O |

P |

Q |

R |

S |

T |

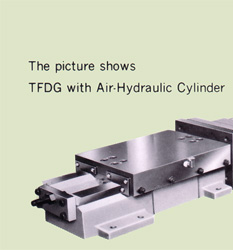

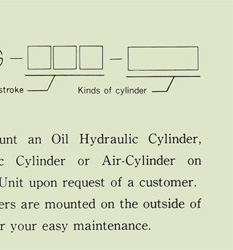

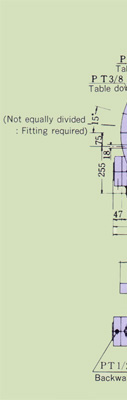

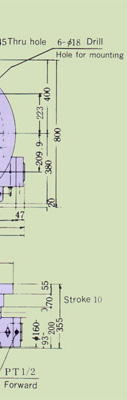

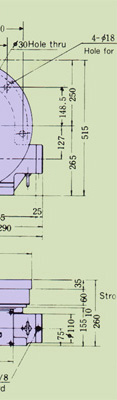

@TFDG

@@- 80 |

Oil |

30kg |

645 |

240 |

10 |

80 |

240 |

10 |

73 |

50 |

50 |

60 |

195 |

35 |

340 |

180 |

150 |

100 |

15 |

24 |

170 |

11 |

| Air |

28kg |

671 |

266 |

| AirEHydraulic |

45kg |

1015 |

610 |

@TFDG

@@-150 |

Oil |

35kg |

820 |

330 |

10 |

150 |

240 |

10 |

96 |

50 |

50 |

60 |

265 |

35 |

410 |

180 |

150 |

100 |

15 |

24 |

170 |

11 |

| Air |

30kg |

806 |

316 |

| AirEHydraulic |

50kg |

1200 |

710 |

@TFDG

@@-250 |

Oil |

40kg |

1065 |

430 |

10 |

250 |

240 |

10 |

131 |

50 |

50 |

60 |

365 |

35 |

510 |

180 |

150 |

100 |

15 |

24 |

170 |

11 |

| Air |

35kg |

1051 |

416 |

| @ |

@ |

@ |

@ |

|

|

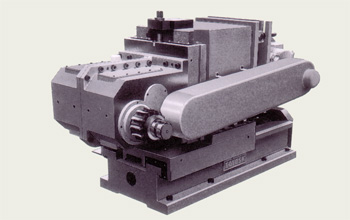

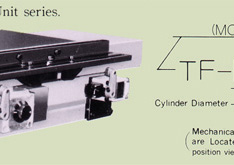

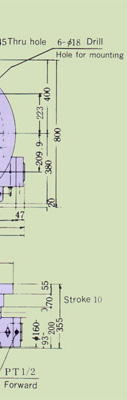

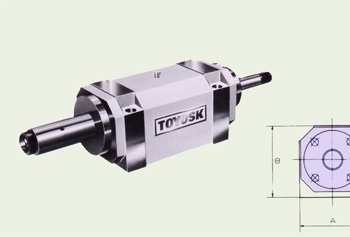

| se FEED UNIT SERIES |

|

| TF feed unit is designed for easy operation through our long-term experiences.

You can choose it among your demand of size, thrust, feed speed or stroke.

It keeps high precise processing to be designed for enough rigidity. It

has a compact body on account of inner cylinder structure and you can maintain

it easily.. |

|

|

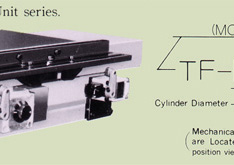

TF

50~160 |

TF

50~250 |

TF

60~160 |

TF

60~250 |

TF

60~400 |

TF

80~160 |

TF

80~250 |

TF

80~400 |

TF

100~250 |

TF

100~400 |

| Weight |

75 |

81 |

150 |

188 |

223 |

277 |

318 |

340 |

550 |

590 |

| Stroke |

160 |

250 |

160 |

250 |

400 |

160 |

250 |

400 |

250 |

400 |

Cylinder

Diameter |

Σ50 |

Σ60 |

Σ80 |

Σ100 |

T

h

r

u

s

t

@@ |

20/u |

372 |

565 |

1,004 |

1,570 |

| 30/u |

588 |

847 |

1,507 |

2,355 |

| 40/u |

784 |

1,130 |

2,009 |

3,140 |

| 50/u |

980 |

1,413 |

2,512 |

3,925 |

|

| Thrusting Power are theoretical values. Practical thrusting power may be

subject to changing due to your operation. |

|

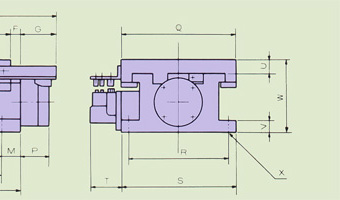

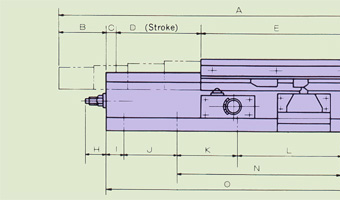

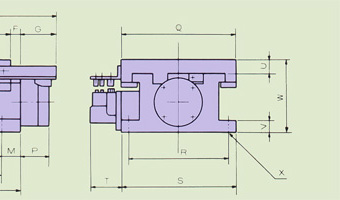

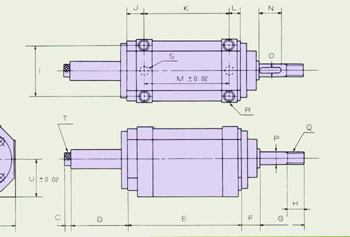

| Model |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

N |

O |

P |

Q |

R |

S |

T |

U |

V |

W |

X |

| TF- 50~160 |

714 |

84 |

20 |

160 |

320 |

25 |

105 |

85 |

40 |

100 |

- |

- |

50 |

335 |

525 |

40 |

200 |

172 |

200 |

85 |

30 |

30 |

150 |

6-Σ12 |

| TF- 50~250 |

905 |

95 |

30 |

250 |

320 |

25 |

185 |

75 |

50 |

150 |

- |

- |

50 |

375 |

625 |

125 |

200 |

172 |

200 |

85 |

30 |

30 |

150 |

6-Σ12 |

| TF- 60~160 |

840 |

90 |

20 |

160 |

420 |

30 |

120 |

80 |

50 |

100 |

- |

- |

50 |

430 |

630 |

40 |

320 |

280 |

320 |

85 |

40 |

35 |

200 |

6-Σ16 |

| TF- 60~250 |

956 |

111 |

10 |

250 |

420 |

30 |

135 |

90 |

50 |

150 |

- |

- |

50 |

460 |

710 |

90 |

320 |

280 |

320 |

85 |

40 |

35 |

200 |

6-Σ16 |

| TF- 60~400 |

1330 |

130 |

20 |

400 |

420 |

30 |

330 |

80 |

50 |

170 |

170 |

380 |

100 |

- |

870 |

240 |

320 |

280 |

320 |

85 |

40 |

35 |

200 |

8-Σ16 |

| TF- 80~160 |

909 |

84 |

20 |

160 |

540 |

30 |

75 |

90 |

50 |

200 |

- |

- |

50 |

450 |

750 |

40 |

400 |

330 |

400 |

85 |

40 |

40 |

230 |

6-Σ20 |

| TF- 80~250 |

1039 |

99 |

20 |

250 |

540 |

25 |

105 |

95 |

50 |

200 |

435 |

100 |

50 |

- |

835 |

40 |

400 |

330 |

400 |

85 |

40 |

40 |

230 |

8-Σ20 |

| TF- 80~400 |

1364 |

134 |

20 |

400 |

540 |

30 |

240 |

95 |

50 |

300 |

440 |

150 |

50 |

- |

990 |

185 |

400 |

330 |

400 |

85 |

40 |

40 |

230 |

8-Σ20 |

| TF- 100~250 |

1178 |

98 |

20 |

250 |

660 |

45 |

105 |

120 |

50 |

300 |

425 |

150 |

50 |

- |

975 |

80 |

500 |

430 |

500 |

85 |

50 |

50 |

270 |

8-Σ22 |

| TF- 100~400 |

1390 |

140 |

20 |

400 |

660 |

45 |

125 |

120 |

50 |

300 |

475 |

250 |

50 |

- |

1125 |

80 |

500 |

430 |

500 |

85 |

50 |

50 |

270 |

8-Σ22 |

|

|

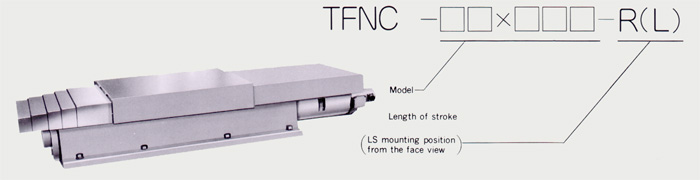

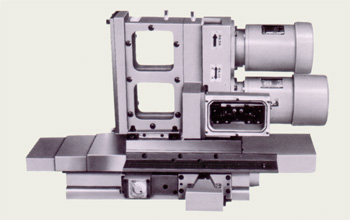

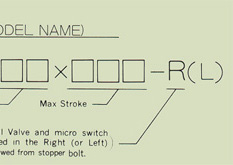

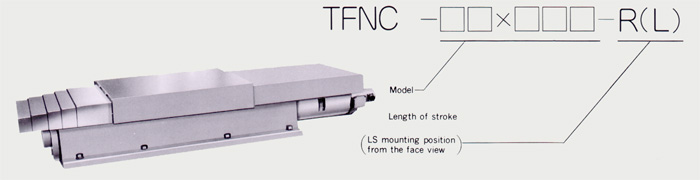

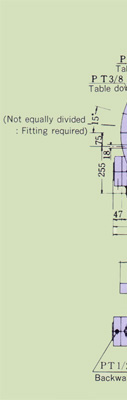

| semb FEED UNIT SERIES |

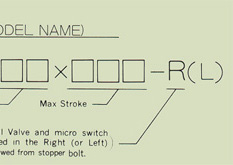

TFNC FEED UNITS are developed for N/C operation through TF UNITS technology.

Please fill the figures in the boxes. |

|

|

|

Stroke |

Feeding UNIT

Width X Length |

Base

Width X Length |

Table

Width X Length |

Total Height |

Weight |

| 60~250 |

250 |

425~1224 |

320~770 |

320~420 |

250 |

290kg |

| 60~400 |

400 |

425~1511 |

320~920 |

320~420 |

250 |

385kg |

| 80~250 |

250 |

505~1409 |

400~885 |

400~540 |

300 |

480kg |

| 80~400 |

400 |

505~1609 |

400~1035 |

400~540 |

300 |

560kg |

| lOO~400 |

400 |

605~1838 |

500~1140 |

500~660 |

310 |

910kg |

|

Controller

@@@TFNC FEED UNIT SERIES consist of SERVO-PACK, F/B cable and AC Servo-Motor

Remarks:

@@@A cabinet of N/C unit and operation panel are not supplied.

@@@AC Servo-motor is an option.

@@@Servomotor has a brake in case of vertical use. |

|

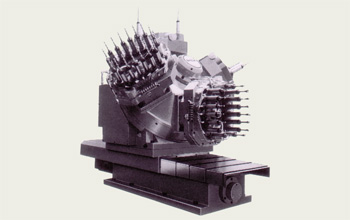

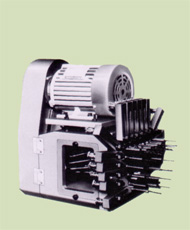

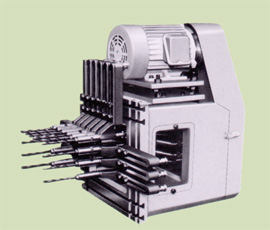

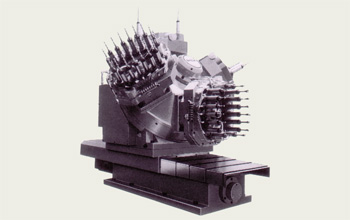

| MULTI-SPINDLE DRILLING UNITS @@MULTI-SPINDLE TAPPING UNITS |

|

|

|

| @TH-01-D |

@TH-O1B-D^ |

@THO-D^ |

|

|

|

| TOYOSKfs technology of manufacturing Multi-Spindle machine is applied to design

Multi-Spindle head unit. Thus the specification of head unit in the processing

ability and area is equivalent to our multi-spindle drilling and tapping

machines. So you can choose them as your demand. There are two types among

the Multi-spindle tapping units. One is a 'Hydraulic control tapping mechanism

type'. The other is a 'master lead screw type'. Please take care that in

case of 'master lead screw type'. One spindle is employed for tapping depth

control except TH-3B and TH-4B. So you have to reduce one spindle from

the number of spindles when the Master Lead Screw Type Spindles are applied. |

|

|

Sketch |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

N |

O |

P |

| @TH|000 |

2 |

100 |

140 |

140 |

116 |

30 |

50 |

150 |

220 |

476 |

97 |

4-Σ9 |

^ |

^ |

^ |

^ |

^ |

| @TH|0 |

2 |

150 |

242 |

165 |

130 |

40 |

60 |

150 |

232 |

560 |

125 |

4-Σ11 |

^ |

^ |

^ |

^ |

^ |

| @TH|06 |

2 |

150 |

242 |

165 |

130 |

40 |

60 |

150 |

232 |

560 |

125 |

4-Σ11 |

^ |

^ |

^ |

^ |

^ |

| @TH|0U |

1 |

130 |

200 |

220 |

150 |

170 |

140 |

25 |

65 |

^ |

^ |

140 |

255 |

310 |

125 |

405 |

4-Σ11 |

| @TH|06U |

1 |

130 |

200 |

220 |

150 |

170 |

140 |

25 |

65 |

^ |

^ |

140 |

255 |

310 |

125 |

405 |

4-Σ11 |

| @TH|01 |

1 |

150 |

230 |

280 |

195 |

195 |

140 |

30 |

60 |

85 |

85 |

^ |

255 |

350 |

125 |

435 |

6-Σ11 |

| @TH|06B |

1 |

180 |

330 |

330 |

180 |

240 |

210 |

10 |

70 |

^ |

^ |

170 |

280 |

390 |

165 |

500 |

4-Σ13 |

| @TH|01B |

1 |

230 |

390 |

440 |

280 |

320 |

240 |

30 |

60 |

120 |

120 |

^ |

360 |

440 |

200 |

620 |

6-Σ14 |

| @TH|01C |

1 |

230 |

390 |

440 |

280 |

320 |

240 |

30 |

60 |

120 |

120 |

^ |

360 |

440 |

200 |

620 |

6-Σ14 |

| @TH|01B B |

1 |

330 |

490 |

490 |

330 |

320 |

260 |

40 |

80 |

160 |

160 |

^ |

460 |

490 |

255 |

695 |

6-Σ14 |

| @TH|01C C |

1 |

330 |

490 |

490 |

330 |

320 |

260 |

40 |

80 |

160 |

160 |

^ |

460 |

490 |

255 |

695 |

6-Σ14 |

| @TH|01B450U |

1 |

250 |

410 |

640 |

480 |

320 |

260 |

30 |

70 |

110 |

110 |

^ |

360 |

400 |

215 |

700 |

6-Σ14 |

| @TH|01C450U |

1 |

250 |

410 |

640 |

480 |

320 |

260 |

30 |

70 |

110 |

110 |

^ |

360 |

400 |

215 |

700 |

6-Σ14 |

| @TH|01B550U |

1 |

250 |

410 |

740 |

580 |

400 |

340 |

30 |

70 |

100 |

140 |

^ |

360 |

400 |

215 |

700 |

6-Σ16 |

| @TH|01C550U |

1 |

250 |

410 |

740 |

580 |

400 |

340 |

30 |

70 |

100 |

140 |

^ |

360 |

400 |

215 |

700 |

6-Σ16 |

| @TH|2B |

1 |

320 |

510 |

600 |

410 |

400 |

340 |

50 |

110 |

160 |

160 |

^ |

480 |

610 |

265 |

790 |

6-Σ16 |

| @TH|3B |

1 |

430 |

630 |

700 |

500 |

400 |

340 |

60 |

110 |

160 |

160 |

^ |

480 |

755 |

325 |

940 |

6-Σ18 |

| @TH|4B |

1 |

500 |

700 |

780 |

580 |

500 |

440 |

80 |

130 |

140+140 |

140 |

^ |

640 |

990 |

370 |

1085 |

8-Σ22 |

|

Specifications of Multi-spindle Drilling unit

| Model |

TH|000 |

TH|0 |

TH|06 |

TH|0U |

TH|06U |

TH|01 |

TH|06B |

Number of Spindle

(@) @Special Type |

6 |

12(15) |

6(9) |

12(15) |

6(9) |

18(22)(30) |

6 |

| Capacity of Drilling |

Σ2.2x6@Σ3~4 |

Σ3~12@Σ4~7 |

Σ5~6@Σ7x3 |

Σ3~12@Σ4~7 |

Σ5~6@Σ7~3 |

Σ3.5~18@Σ4~12 |

Σ6~6@Σ10~3 |

| Working Area |

Σ80 |

Σ135 |

Σ125 |

115X135 |

105X125 |

130~180 |

150~150 |

| Min. Spindle Distance |

6.5 |

6.5 |

14 |

6.5 |

14 |

6.5 |

20 |

Spindle Speed

(rDDD) |

3300

4000 |

3300

4000 |

1950

2300 |

1600@2500@3500

1900@3000@4200 |

800@1200@1700

960@1400@2000 |

1600@2500@3500

1900@3000@4200 |

670@1200@1700

800@1400@2000 |

| Main Motor |

0.2-4 p |

0.4-6 p |

0.4-4 p |

0.4-4 p |

0.4-4 p |

0.75-4 p |

0.75-4 p |

| Sketch |

2 |

2 |

2 |

1 |

1 |

1 |

1 |

| Weight |

30kg |

45kg |

45kg |

50kg |

50kg |

60kg |

70kg |

|

Specifications of Multi-spindle Tapping Unit

| Model |

TH|000 |

TH|0 |

TH|06 |

TH|0U |

TH|06U |

TH|01 |

TH|06B |

Number of Spindle

(@) @Special Type |

6 |

12 |

6(9) |

12 |

6(9) |

18(22)(30) |

6 |

| Capacity of Tapping |

M2~6@M2.6~4 |

M2~12@M4~6 |

M4~6@M6~3 |

M2~12@M4~6 |

M4~6@M6~3 |

M2~18@M4~10 |

M5x6@M8x3 |

| Working Area |

Σ80 |

Σ130 |

Σ125 |

115~135 |

105~125 |

130~180 |

150~150 |

| Min. Spindle Distance |

8 |

8 |

14 |

8 |

14 |

8 |

20 |

Spindle Speed

(rDDD) |

830

1000 |

800

1000 |

600

720 |

490@710@1080

600@860@1310 |

440@830

530@1000 |

570@1250

680@1500 |

210@400@550

250@470@660 |

| Main Motor |

0.2-4 p |

0.4-4 p |

0.4-4 p |

0.4-6 p |

0.4-6 p |

0.75-6 p |

0.75-6 p |

| Sketch |

2 |

2 |

2 |

1 |

1 |

1 |

1 |

| Weight |

35kg |

50kg |

50kg |

55kg |

55kg |

65kg |

75kg |

|

Specifications of Multi-spindle Drilling unit

| TH-01B |

TH|01C |

TH|01B B |

TH|01C C |

TH|01B450U |

TH|01C450U |

TH|2B |

TH|3B |

TH|4B |

| 12(16)(24) |

18(22)(30)(38) |

12(16)(24) |

22(30)(38) |

24 |

26 |

14(22) |

14(8)(24) |

14(24) |

| Σ6X12 Σ10X6 |

Σ4X18 |

Σ6X12 Σ10X6 |

Σ4X18 |

Σ4,5X24 Σ10X6 |

Σ3X26 Σ5.5X10 |

Σ16X5 Σ10X14 |

Σ16X10 Σ14X14 |

Σ26X6 |

| 200~250 |

200~250 |

300~300 |

300~300 |

220~450 |

220x450 |

280~350 |

380~450 |

450~530 |

| 20 |

6.5 |

20 |

6.5 |

20 |

6.5 |

20 |

30 |

45 |

920 1300 1900

1100 1630 2300 |

1700@2500@3500

2100@3000@4200 |

920@1300@1900

1100@1630@2300 |

1700@2500@3500

2100@3000@4200 |

900@1350@1910

1100@1630@2300 |

1700@2500@3500

2100@3000@4200 |

340@510

410@620@ |

230-1300iΰ-¬j

280-1600iΰ-¬j |

188-933iΰ-¬j

226-1120iΰ-¬j |

| 1.5-4 P |

1.5-4 P |

1.5-4 P |

1.5-4 P |

1.5-4 P |

1.5-4 P |

3,7-4 P |

5.5-6 P |

7.5-6 P |

| 1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

| 160kg |

160kg |

200kg |

200kg |

250kg |

250kg |

300kg |

550kg |

700kg |

|

Specifications of Multi-spindle Tapping Unit

| TH-01B |

TH|01C |

TH|01B B |

TH|01C C |

TH|01B450U |

TH|01C450U |

TH|2B |

TH|3B |

TH|4B |

| 12(16)(24) |

18(22)(30)(38) |

12(16)(24) |

22(30)(38) |

24 |

26 |

14(22) |

14(8)(24) |

14(24) |

| M5~12@M8x6 |

M3~18@M4x12 |

M5X12@M8~6 |

M3X18@M4~12 |

M4~24@M5~18 |

M3~26@M5~16 |

M10~8@M6~14 |

M14~10 |

M20x6@M14~12 |

| 200~250 |

200~250 |

300~300 |

300~300 |

220~450 |

220~450 |

280~350 |

380~450 |

450~530 |

| 20 |

8 |

20 |

8 |

20 |

8 |

20 |

30 |

30 |

360@500@830

440@700@990 |

430@710@1030

520@850@1230 |

360@580@830

490@700@1000 |

430@710@1030

520@850@1230 |

350@560@800

420@670@960 |

430@700@1000

520@840@1200 |

120@170

140@200 |

105-630

125-750 |

100-500

120-598 |

| 1.5-6 P |

1.5-6 P |

1.5-6 P |

1.5-6 P |

2.2-6 P |

2.2-6 P |

3.7-6 P |

5.5-6 P |

7.5-6 P |

| 1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

| 175kg |

175kg |

215kg |

215kg |

265s |

265kg |

325kg |

570kg |

750kg |

|

|

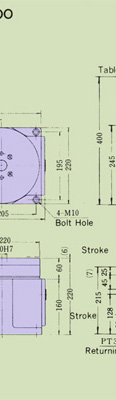

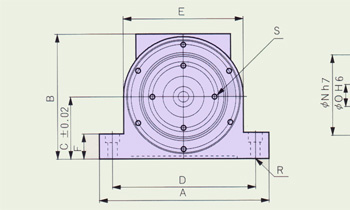

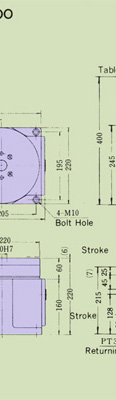

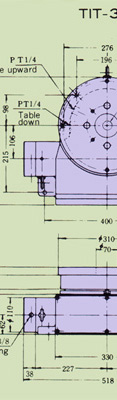

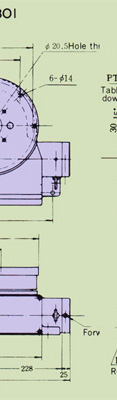

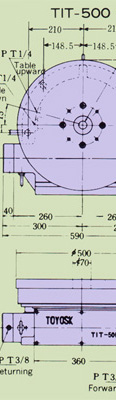

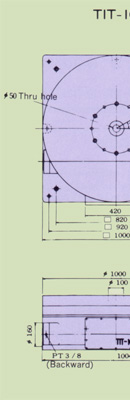

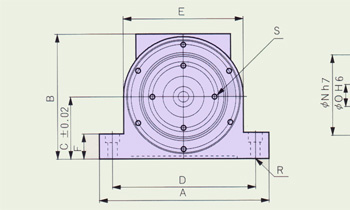

| INDEX TABLES |

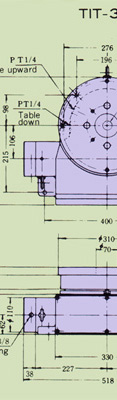

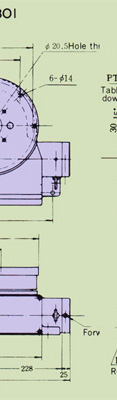

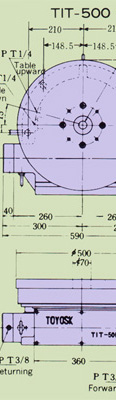

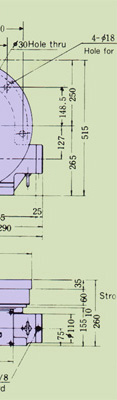

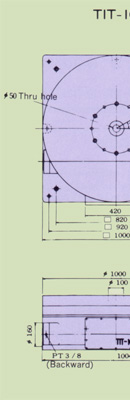

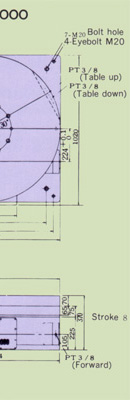

| TIT-200, TIT-301, TIT-500, TIT-800 and TIT-1000 have been developed to

meet multi-spindle, multi-tapping and various special-purpose machines.

It has a coupling gear to comply with accurate indexing, heavy cutting,

smooth turning by cushion mechanism and easy maintenance as well as easy

application of these devices to various TOYOSKmachines. |

|

| Model |

shs|200 |

shs|301 |

shs|500 |

| Table Diameter@(mm) |

200 |

310 |

500 |

| Height@(mm) |

200 |

215 |

260 |

| Number of Index |

4D6 |

3D4D5D6D8D10 |

3D4D5D6D8D10 |

| Diameter of Center Hole |

Σ30H5~10 |

Σ70H5~20 |

Σ70H5~30 |

| Indexing Accuracy |

}6iOPTIONAL }3) |

}6iOPTIONAL }3j |

}6iSpecial class}3j |

| Parallel between Table Surface & bottom |

0.02 |

0.02 |

0.02 |

| Table drive System |

Motor |

Air or Hydraulic |

Hydraulic |

| Turning direction |

Clockwise |

Clockwise |

Clockwise |

| Weight |

60kg |

120kg |

240kg |

| Max Loading Capacity |

20kg |

Hydraulic 400kg@@Air 150kg |

Hydraulic 1,000kg |

|

|

| Model |

shs|800 |

shs|1000 |

| Table Diameter@(mm) |

800 |

1000 |

| Height@(mm) |

355 |

370 |

| Number of Index |

4D5D6D8D10D12 |

4D6D8D12 |

| Diameter of Center Hole |

Σ70H5~50 |

Σ100H5~40 |

| Indexing Accuracy |

}6iSpecial class }3) |

}6iSpecial class }3j |

| Parallel between Table Surface & bottom |

0.02 |

0.02 |

| Table drive System |

Hydraulic |

Hydraulic |

| Turning direction |

Clockwise |

Clockwise |

| Weight |

700kg |

900kg |

| Max Loading Capacity |

Hydraulic 2,500kg |

Hydraulic 2,500kg |

|

|

|

Single Spindle Drilling Units |

TOYOSK Single Spindle Drilling Units have been designed specially for accurate

works on drilling, spot facing, reaming, chamfering, etc. There are four

standard models, TSD-1, TSD-1-H (High Speed Type), TSD-2, TSD-3.

We will assemble Single Spindle Drilling Units with Motors and Feeding

units upon your request. Our sales engineers will satisfy your requests.

Please consult us. |

|

|

|

Max Drilling

Capacity |

Spindle

Speed |

` |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L |

M |

N |

O |

P |

Q |

q |

r |

s |

U |

Weight |

| max |

min |

| TSD-1-H |

Σ5.5 |

6000 |

100 |

110 |

30 |

10 |

90 |

202 |

30 |

73 |

28 |

80 |

27.5 |

154 |

20.5 |

154 |

45 |

5 |

Σ20

h7 |

M20 |

Σ11 |

Σ12H7

Dep.12 |

Collet

chuck |

60 |

20kg |

| TSD-1 |

Σ14 |

3000 |

100 |

110 |

30 |

10 |

90 |

202 |

30 |

73 |

28 |

80 |

27.5 |

154 |

20.5 |

154 |

45 |

5 |

Σ20

h7 |

M20 |

Σ11 |

Σ12H7

Dep.12 |

ls-1 |

60 |

20kg |

| TSD-2 |

Σ23 |

2500 |

120 |

130 |

30 |

10 |

106 |

240 |

39 |

97 |

35 |

96 |

32.5 |

175 |

32.5 |

175 |

55 |

7 |

Σ24

h7 |

M24 |

Σ13 |

Σ15H7

Dep.15 |

ls-2 |

70 |

30kg |

| TSD-3 |

Σ32 |

2000 |

150 |

145 |

30 |

10 |

125 |

280 |

43 |

117 |

37 |

123 |

40 |

200 |

40 |

200 |

75 |

7 |

Σ28

h7 |

M24 |

Σ13 |

Σ15H7

Dep.15 |

ls-3 |

80 |

40kg |

|

|

|

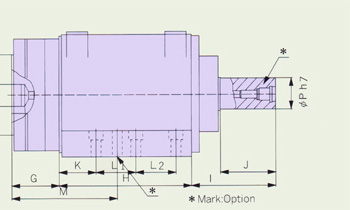

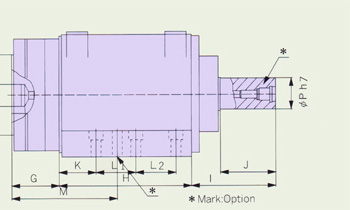

Boring Spindle |

TOYOSK's boring spindle is developed for composing special machine with double

cylindrical roller bearing and double angular ball thrust bearing (SFK

product). This permits high-speed revolution by grease lubricating and

realizes high accuracy and high revolution.

This boring spindle is available for either rough boring or finish boring

and various use. Coolant spout type spindle is also available. Do not hesitate

to ask TOYOSK engineer for concrete specification and further information.

@@1.Spindle of bearings are equipped with TNB body directly.

@@2.They are done with main body as TNB-C type spindle quill. |

|

| @ |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

L1 |

L2 |

M |

N |

O |

P |

Q |

R |

PDbDc |

MAX.RPM

iGreasej |

| TNB- |

40 |

160 |

165 |

90 |

130 |

| |

40 |

50 |

170 |

113 |

80 |

55 |

85 |

| |

| |

98 |

25 |

28 |

20 |

4-Σ16C

Σ24~10k |

4-M10

PCD 80 |

4500 min-1 |

| 50 |

170 |

170 |

90 |

140 |

| |

40 |

50 |

195 |

127 |

90 |

55 |

110 |

| |

| |

118 |

30 |

35 |

25 |

4-Σ16C

Σ24~10k |

4-M10

PCD 100 |

4000 min-1 |

| 60 |

190 |

195 |

105 |

155 |

| |

50 |

55 |

235 |

137 |

100 |

60 |

140 |

| |

| |

128 |

30 |

45 |

25 |

4-Σ18C

Σ26~10k |

4-M10

PCD 110 |

3400 min-1 |

| 60C |

280 |

210 |

105 |

240 |

200 |

45 |

80 |

210 |

137 |

100 |

45 |

140 |

| |

195 |

128 |

30 |

45 |

25 |

4-Σ18C

Σ26~18k |

4-M10

PCD 110 |

3500 min-1 |

| 75C |

320 |

240 |

120 |

270 |

230 |

50 |

90 |

250 |

160 |

105 |

70 |

150 |

| |

230 |

156 |

40 |

60 |

25 |

4-Σ18C

Σ26~18k |

4-M10

PCD 120 |

2800 min-1 |

| 85C |

340 |

260 |

130 |

290 |

250 |

50 |

100 |

300 |

170 |

115 |

60 |

100 |

100 |

220 |

142 |

40 |

70 |

25 |

6-Σ18C

Σ26~18k |

6-M10

PCD 120 |

2500 min-1 |

| 100C |

370 |

290 |

145 |

320 |

280 |

50 |

100 |

345 |

180 |

125 |

60 |

125 |

125 |

220 |

204 |

50 |

85 |

30 |

6-Σ18C

Σ26~18k |

6-M12

PCD 170 |

2200 min-1 |

|

|

|

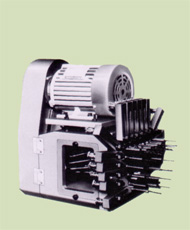

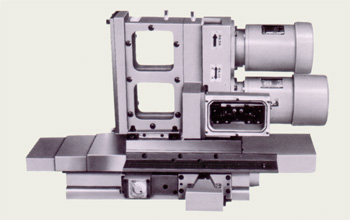

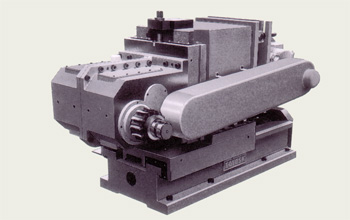

Special Units |

| TOYOSK is manufacturing Special Units as well as the standard units in series

to meet your various requirements. We are glad to arrange machine combination

through our long-term experiences and technology. Please consult us. |

|

Turret unit with 4 stations

This unit is suitable for drilling, reaming, chamfering,

spot facing and tapping at continuous operation.

You can install this unit on the machining lines

like FMS or the special machining flow line.. |

|

Robot for loading, unloading and transferring

This is available for loading, unloading and transferring work pieces.

UNITALL is a robot made in TOYOSK |

|

SPECIAL DRILLING

AND TAPPING UNIT

This unit is designed for installing

the special-purpose machining lines.

We can design special unit

suitable for customers' demand.. |

|

BORING AND MILLING UNIT

This unit is specially designed in accordance

with the customer's requirements.

The high rigid machine is manufactured by

TOYOSK's long-term accumulated technology

and the most suitable bearing system. |