|

TOYOSK Special Machines and Units |

| Multi Station Type Special Machine |

|

|

Transfer Machine

Rotary Index Table

Trunnion Type Special Machine

Shuttle Type Special Machine |

| Single Station Type Special Machine |

|

|

|

One Direction Special Machine

Two Direction Special Machine

Multi-Direction Special Machine |

| FR・FS Type Combination Machine |

|

|

|

FR Type

Multi-spindle Combination Machine

FS Type

Multi-spindle Combination Machine |

|

| Units |

|

|

|

|

| Multi-spindle Drilling Unit |

Feed Unit |

Rotary Index Table |

Drilling Spindle Unit |

|

|

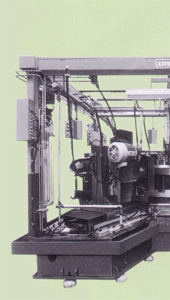

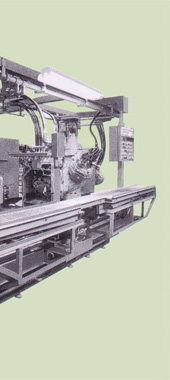

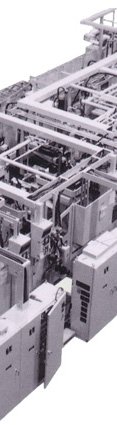

| TRANSFER MACHINE |

|

This is a transfer machine of "pallet transfer type" which dose

drilling, tapping, milling, and boring of automobile parts efficiently

and flexibly.

This machine is composed of some TOYOSK's machines. There are 2 Machining

Centers of "THMC-402", 3 Machining Centers of "THMC-303",

2 Turret Centers of "TTSH-631", 7 Multi-spindle Units and 2 Milling

Units.

This machine also maintains high quality for machining accuracy with accurate

interpolation at each pallet by "sequencer data link system". |

|

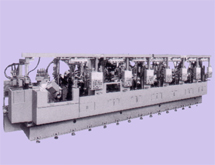

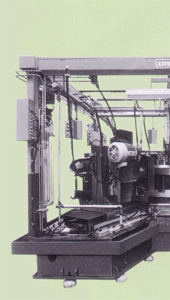

| FTL TRANSFER MACHINE |

|

This machine clamps a work piece automatically and discriminates the kind

of work piece automatically. A work piece is also loaded automatically.

This machine is composed of NC Milling Machine, Gun Drilling Machine, NC

Drilling Machine, Reaming Special Machine, Turret special Machine, Machining

Center of NC Tilt Spindle and Washing Machine.

This is a high accurate and flexible transfer line type machine that produces

various kinds of work pieces at random by "work piece data link system".

Each machine has "turret turning system" or "turret upside-down

turning system".

Especially, Machining center of NC Tilt Spindle newly developed has a flexibility

of machining on upper surface, inclined surface, side surface and any degree

surface. |

MACHINING CENTER OF NC TILT SPINDLE MACHINING CENTER OF NC TILT SPINDLE |

|

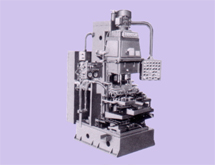

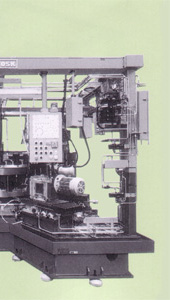

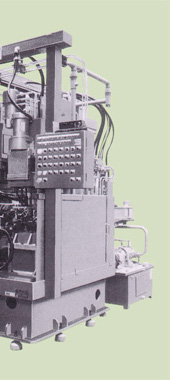

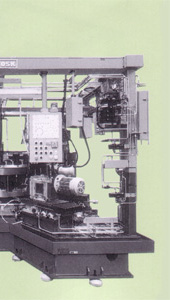

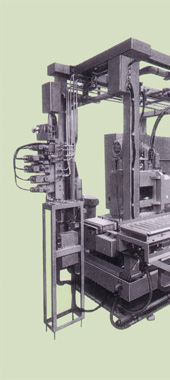

| Rotary Index Type Special Machine |

|

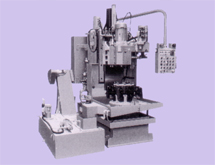

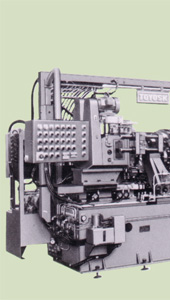

Trunnion Type Special Machine |

|

|

|

| This machine with a 6-station rotary index table is specially designed

for drilling, milling, boring and tapping. The fixtures controlled a hydraulic

system clamp the workpiece automatically at the machining stations and

unclamp it at the loading and unloading stations. |

|

This Special Machine can drill, chamfer, ream and tap at Trunnion Type

Index Table.

The machine receives a work piece from the one machine and feeds out to

another machine automatically after finish of machining.

The machine also inspects the breakage of tools at every process. |

|

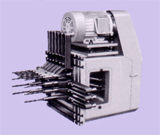

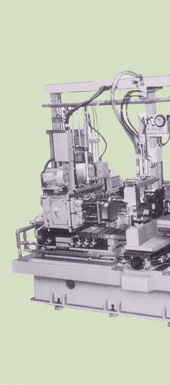

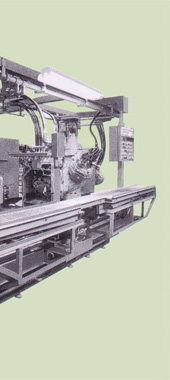

| Shuttle Type Special Machine |

|

One-way Special Machine |

|

|

|

The shuttle table is mounted between the opposed combined units, drilling

and tapping.

The units drill and tap both of the surfaces of the work piece simultaneously

on the shuttle table.

After machining, the work piece is ejected automatically. |

|

With a special purpose milling spindle of vertical type, this machine mills

the top side of the workpiece by moving the X, Y and Z columns under CNC

control.

The automatic natural clamp mechanism automatically clamps the workpiece.

Thus the machine assures high efficiency. |

|

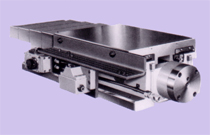

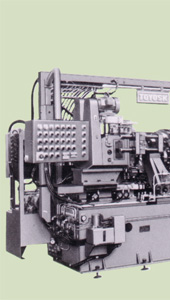

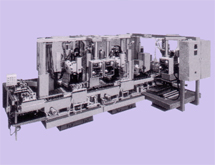

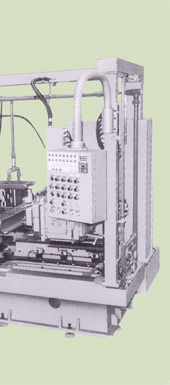

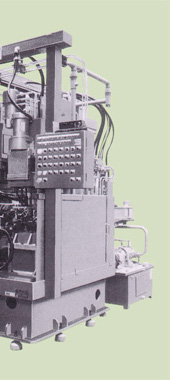

| Two Direction Special Machine |

|

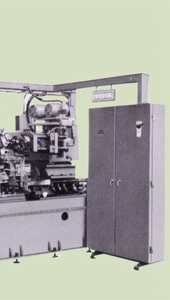

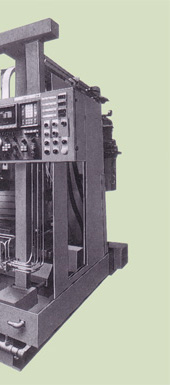

Multi-direction Fully

Automatic Special Machine |

|

|

|

| The work piece machined in the previous process is conveyed on the roller

conveyor and automatically fed into the fixture. After checking for proper

positioning and clamping, the machine drills and taps the work piece from

two directions simultaneously. Upon completion of machining the work piece

is automatically ejected from the fixture and conveyed on the roller conveyor

to the next process. The right side unit with a turret head drills and

taps two types of work pieces by selecting the 1st and 2nd stations or

3rd and 4th stations. |

|

This machine for drilling, reaming, chamfering, and tapping can do all

operations of indexing, positioning, clamping, work feeding and ejection.

Especially, this full-automatic special machine detects the reference position

for the work piece automatically. |

|

|

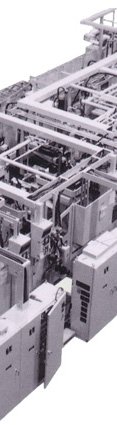

| MACHINING CENTER AND GANTRY LOADER FMS |

|

This machine is composed of 6 high speed Machining Centers, NC washing

machines, Inspecting machines, Work piece stocker, Processed work piece

stocker, Line to line carrier and Pallet carrier.

This FMS line can machine various work pieces full-automatically to carry

work piece directly by gantry type loader.

Each machine is controlled by "sequencer data link system" |

MACHINING CENTER OF NC TILT SPINDLE

MACHINING CENTER OF NC TILT SPINDLE