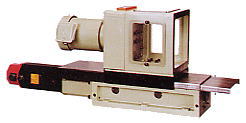

- The single-shaft NC unit for head feed and the inverter for spindle revolution

accomplish quick response to diverse drilling conditions.

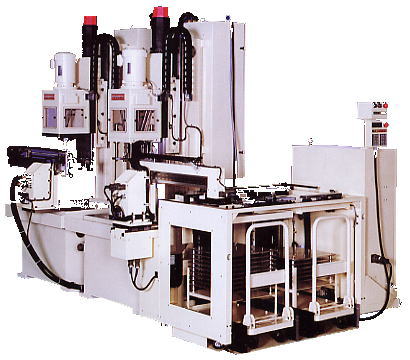

- The vertical unit and the horizontal unit can be combined to create an

optimum layout for your machining application.

- The peripheral equipment, such as loading robot and 180°turning table,

have been turned into modules to promote easier formation of automated

labor-saving systems. Hence this machine is well suited to the operations

that require short start-up time.

- The MD high-speed spindle, boasting of 20000 min-1 revolution speed, will prove useful in drilling small holes in nonferrous

alloy materials.

- This machine makes no use of hydraulic or pneumatic systems. The electrical

equipment and coolant system are all incorporated in the machine to maximize

energy saving and space saving.

|